What is a thermal break?

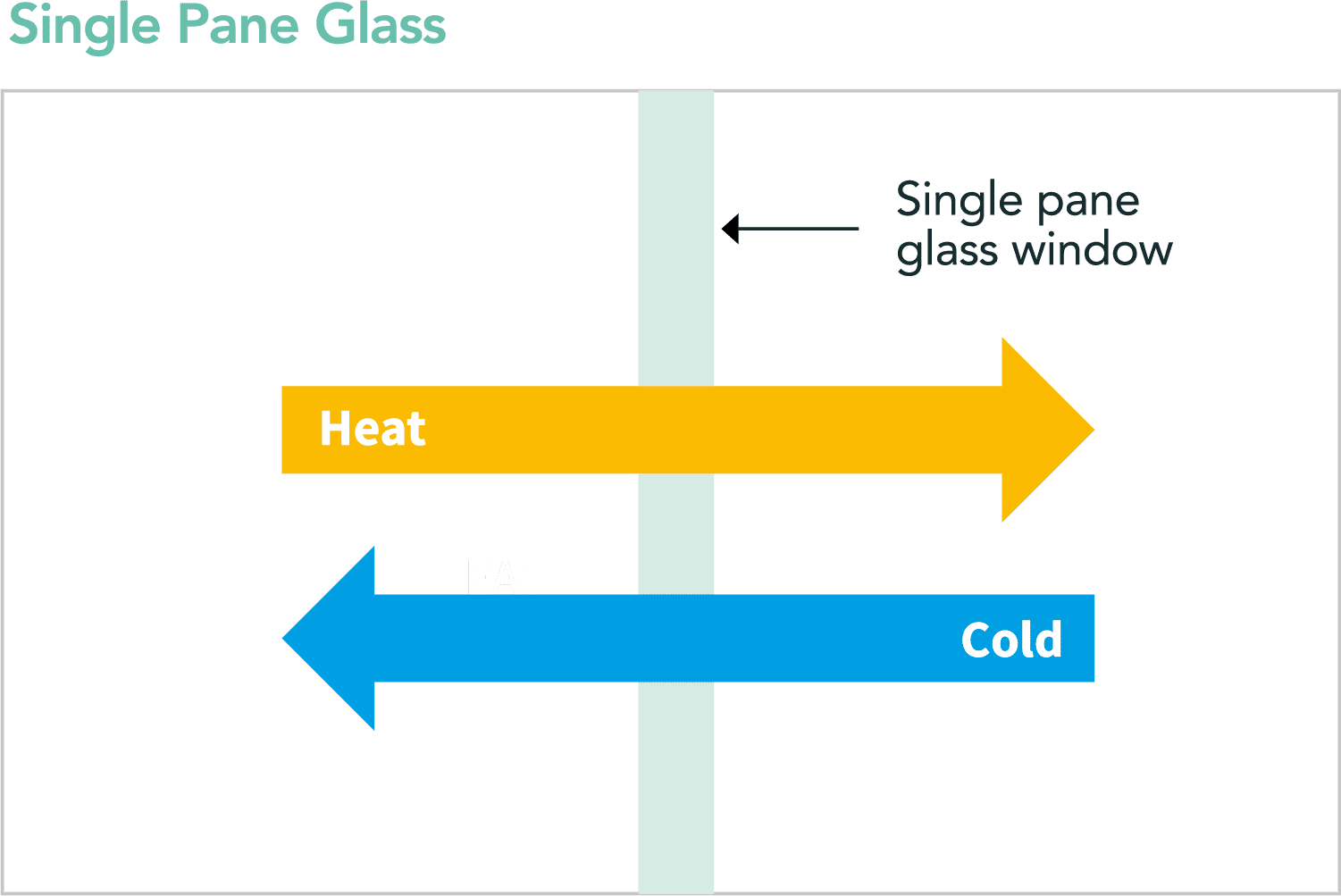

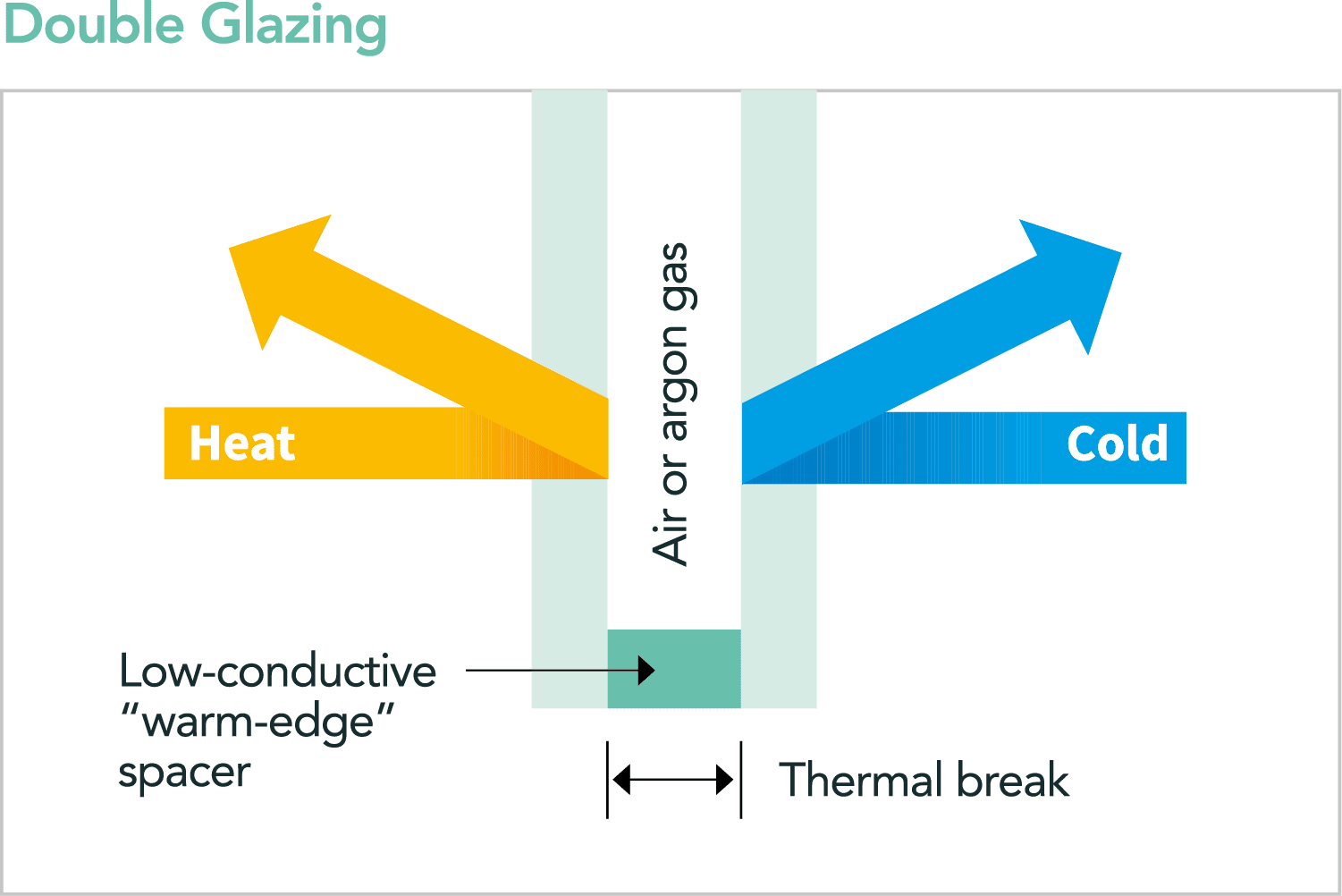

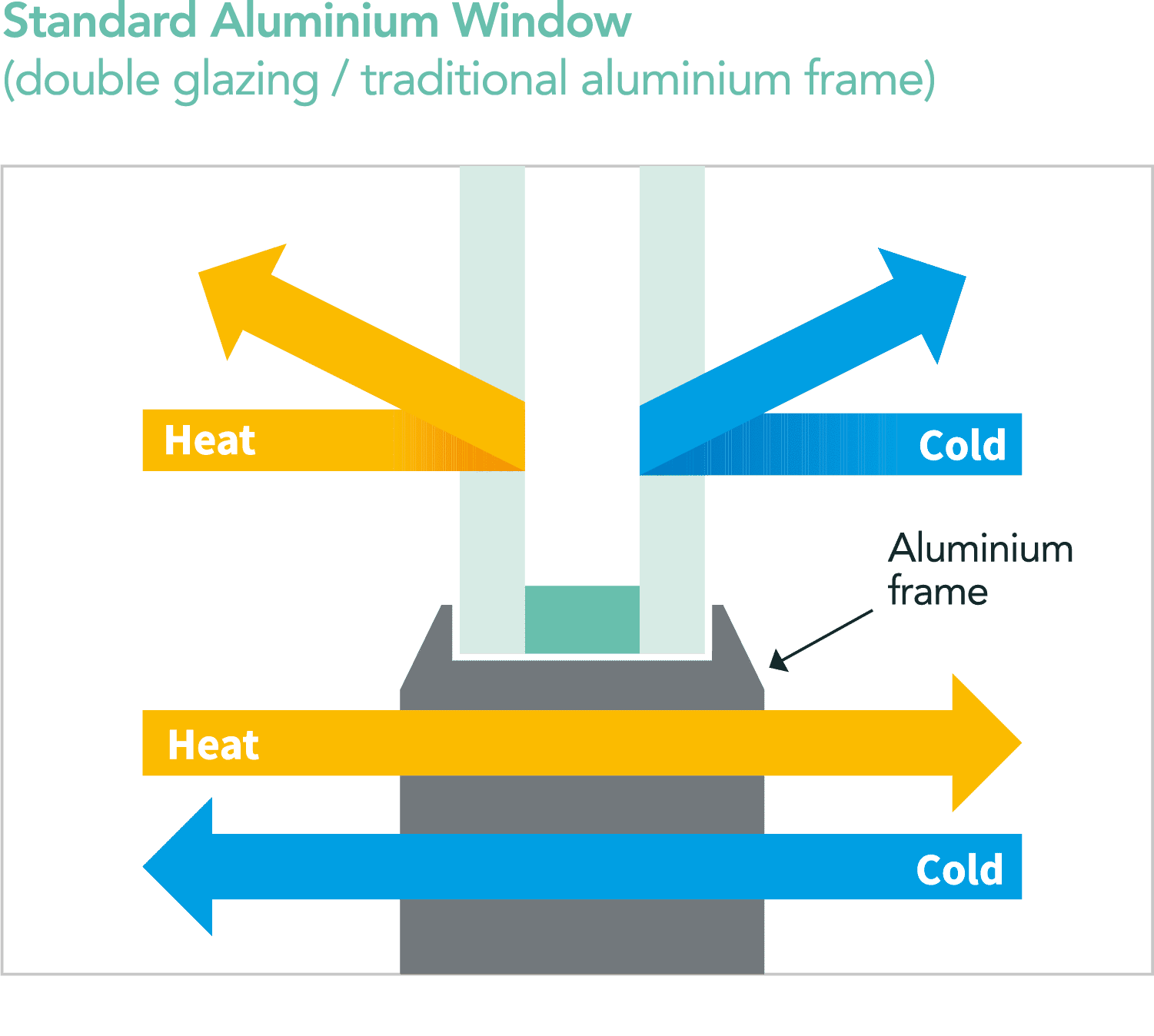

For many years double glazed windows have been used to keep buildings cool in summer and warm in winter.

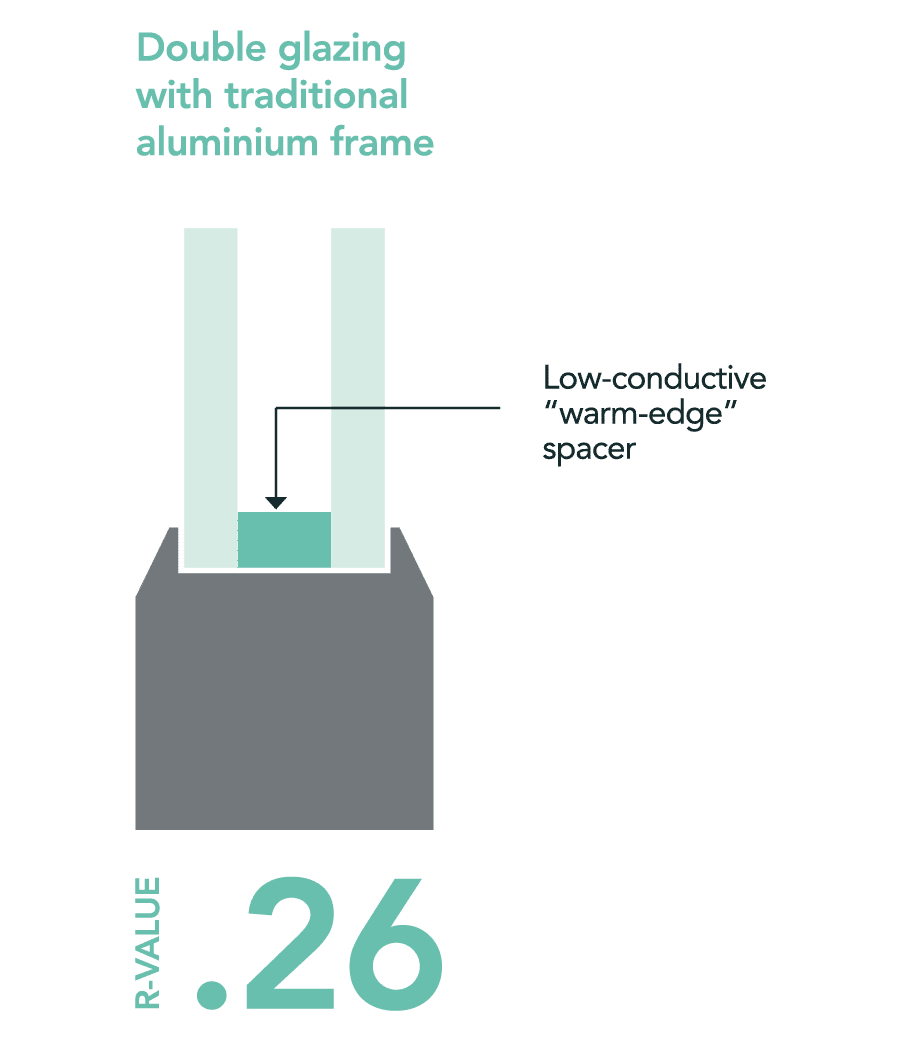

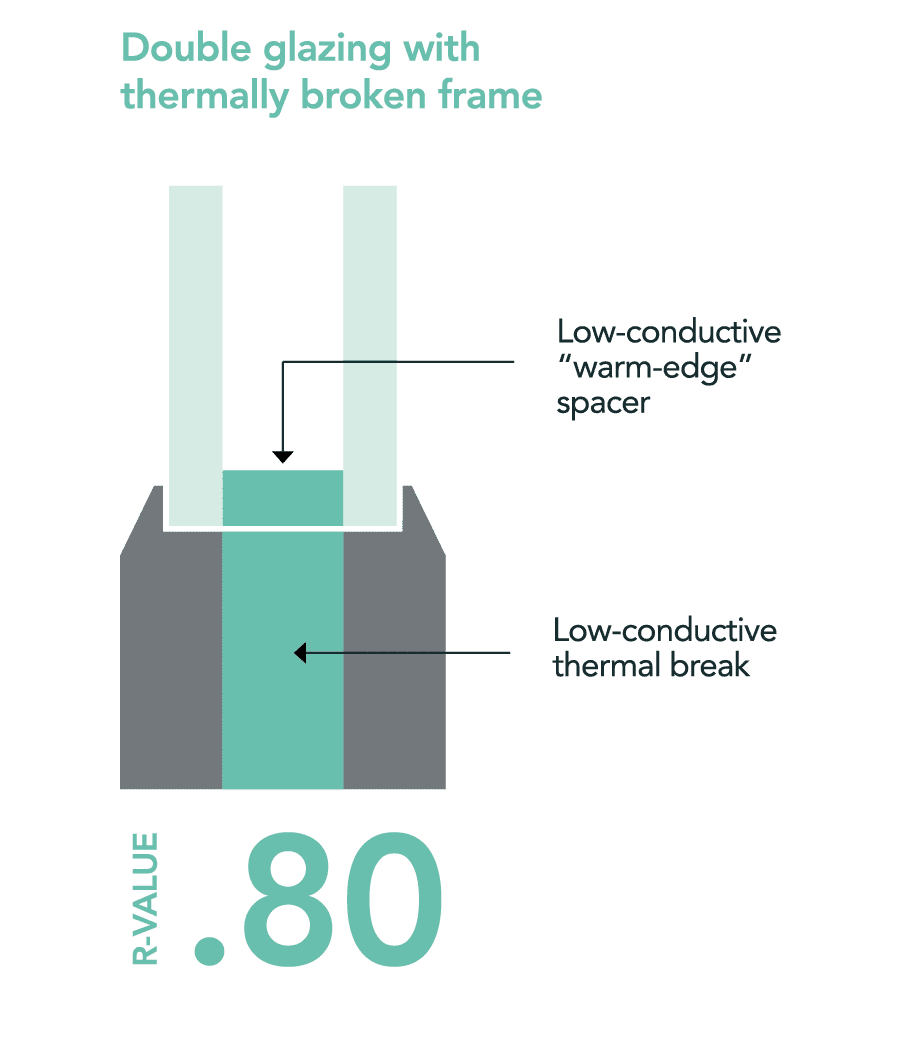

By capturing a layer of air (or argon gas) between two panes of glass separated by non-conductive spacers, double glazed windows interrupt the transfer of heat via the process of conduction. This technique of separating heat conductive materials (like glass) with materials that are poor heat conductors is referred to as a “Thermal Break”.

Double Glazing only solves part of the problem

While double glazing is relatively common, what’s not widely known is that the same thermal break technique can be applied to window frames which like glass are highly heat conductive.

If you’ve ever felt the inside of your aluminum joinery on a cold day, you’ll notice it feels cold, just like outside. So, while your double-glazed glass might be doing an excellent job, its performance is being compromised by heat transfer via conduction from the frame itself.

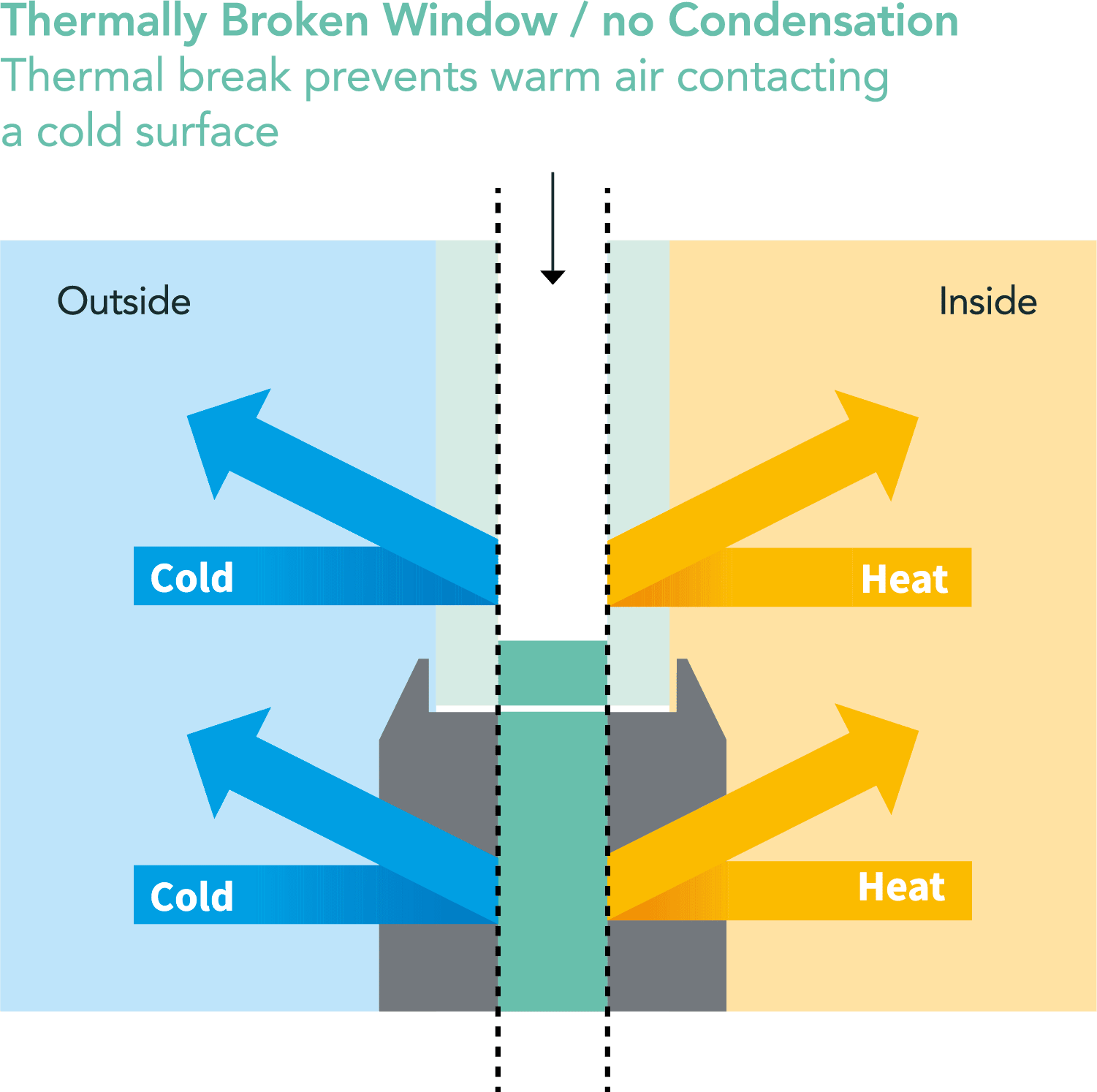

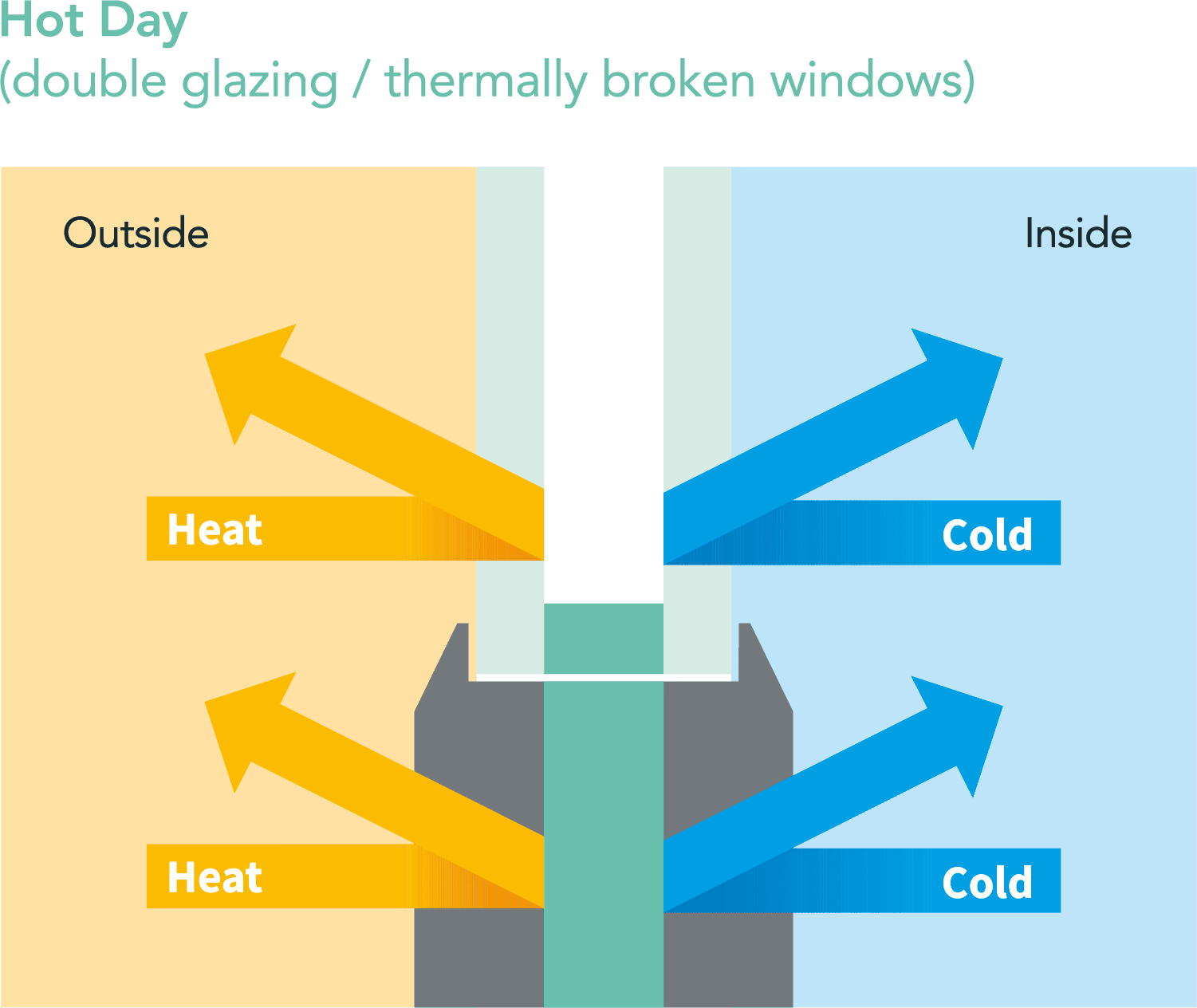

The solution is thermally broken windows

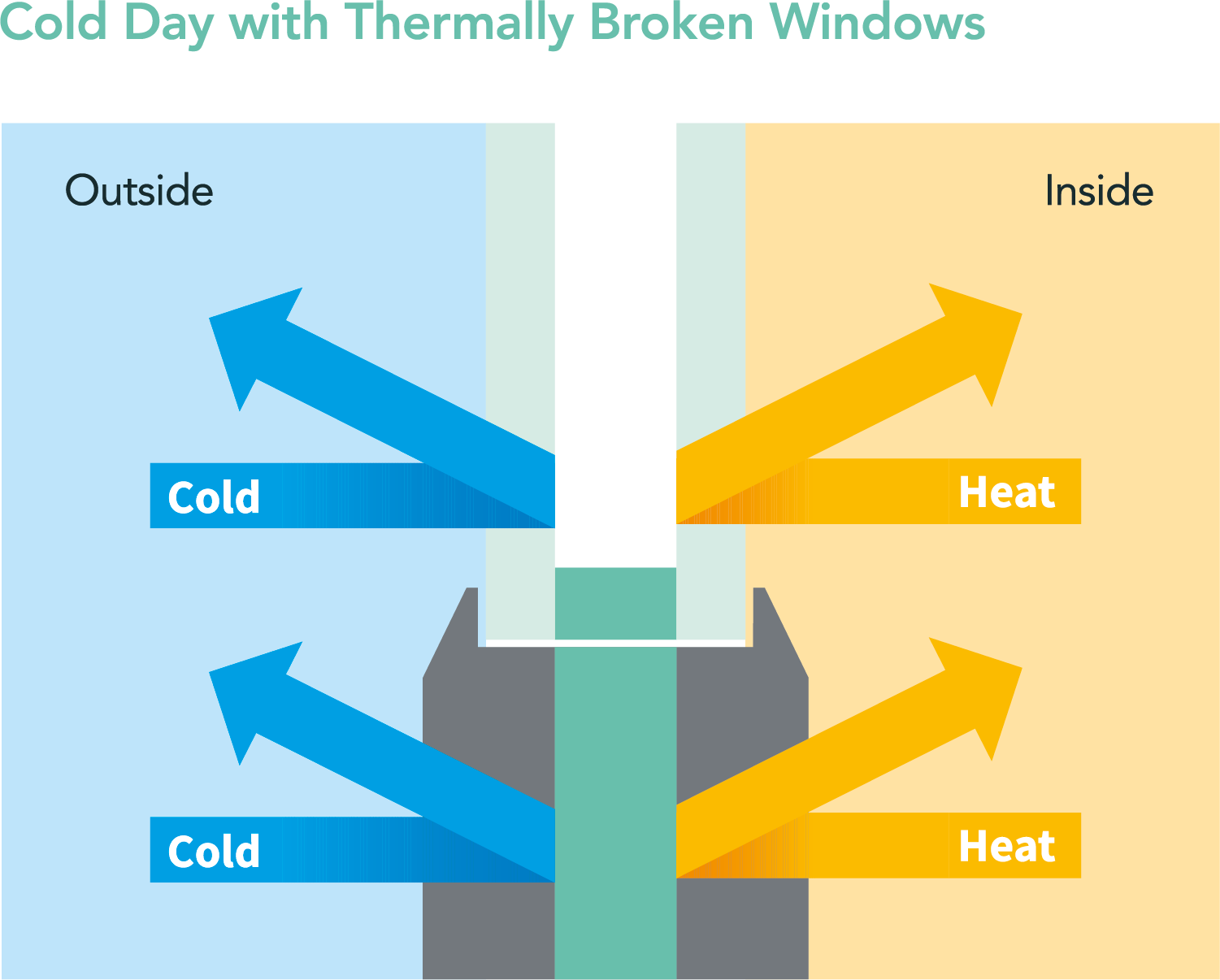

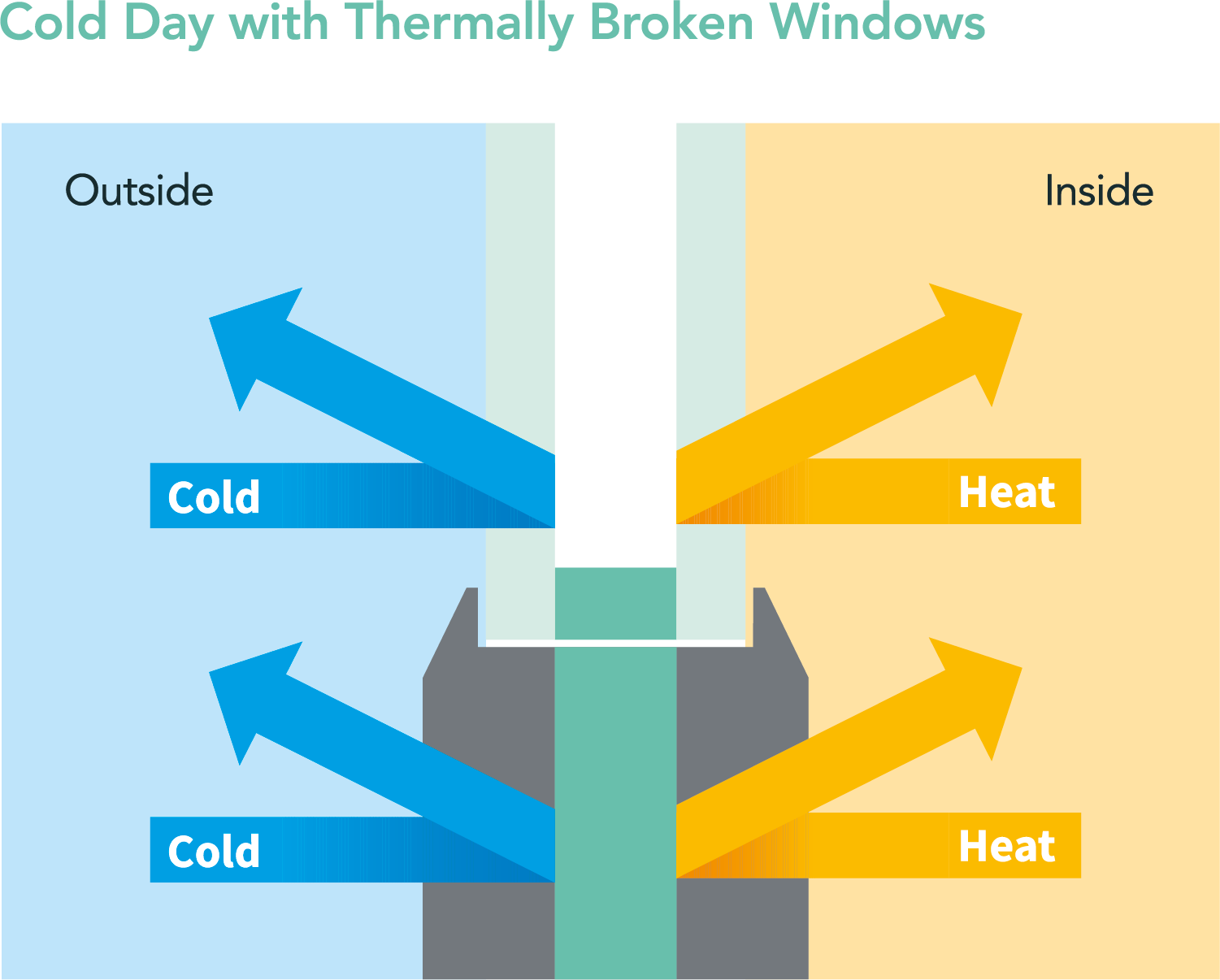

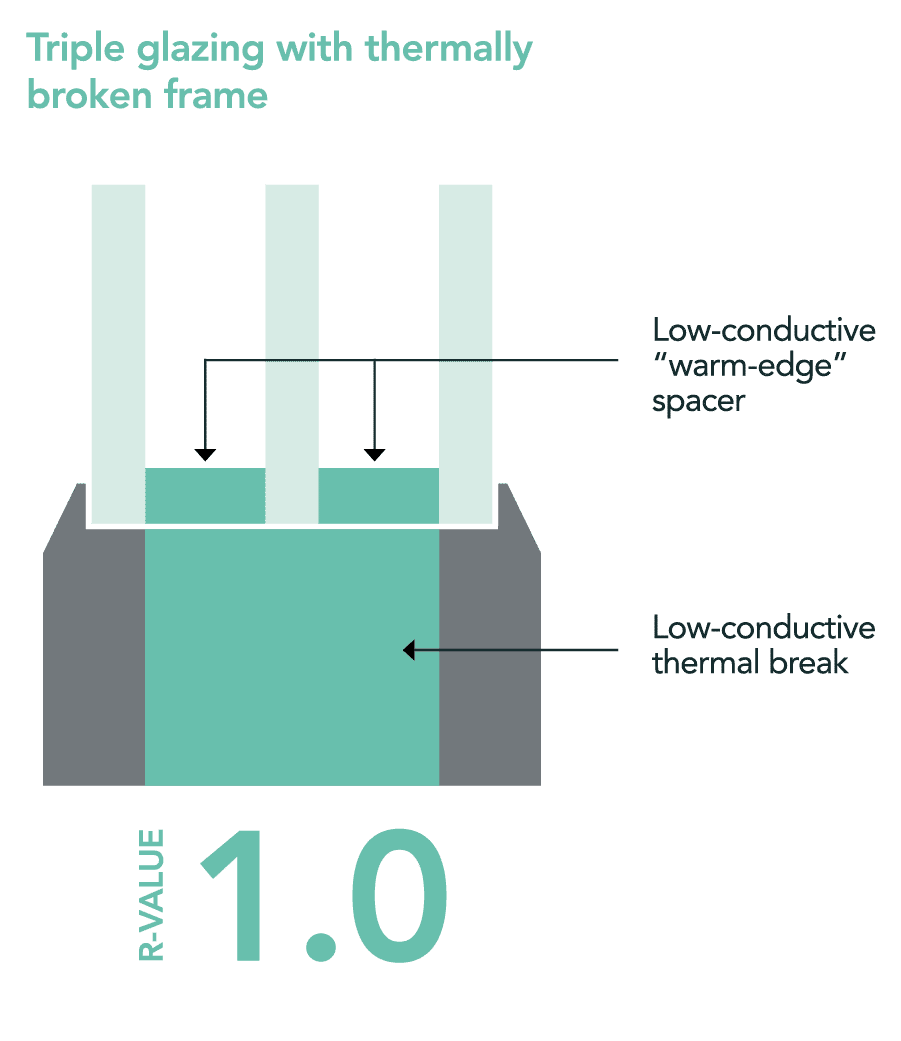

By applying the same thermal break technique used in double glazing to separate the inside and outside surfaces of your window frame with a layer of another material that’s a poor heat conductor, heat transfer through the entirety of the window is reduced. So, the term ‘Thermally Broken Window’ refers to a window that has a thermal break in both the frame, and the glass.

What benefits can you expect from thermally broken windows?

Warmer in winter

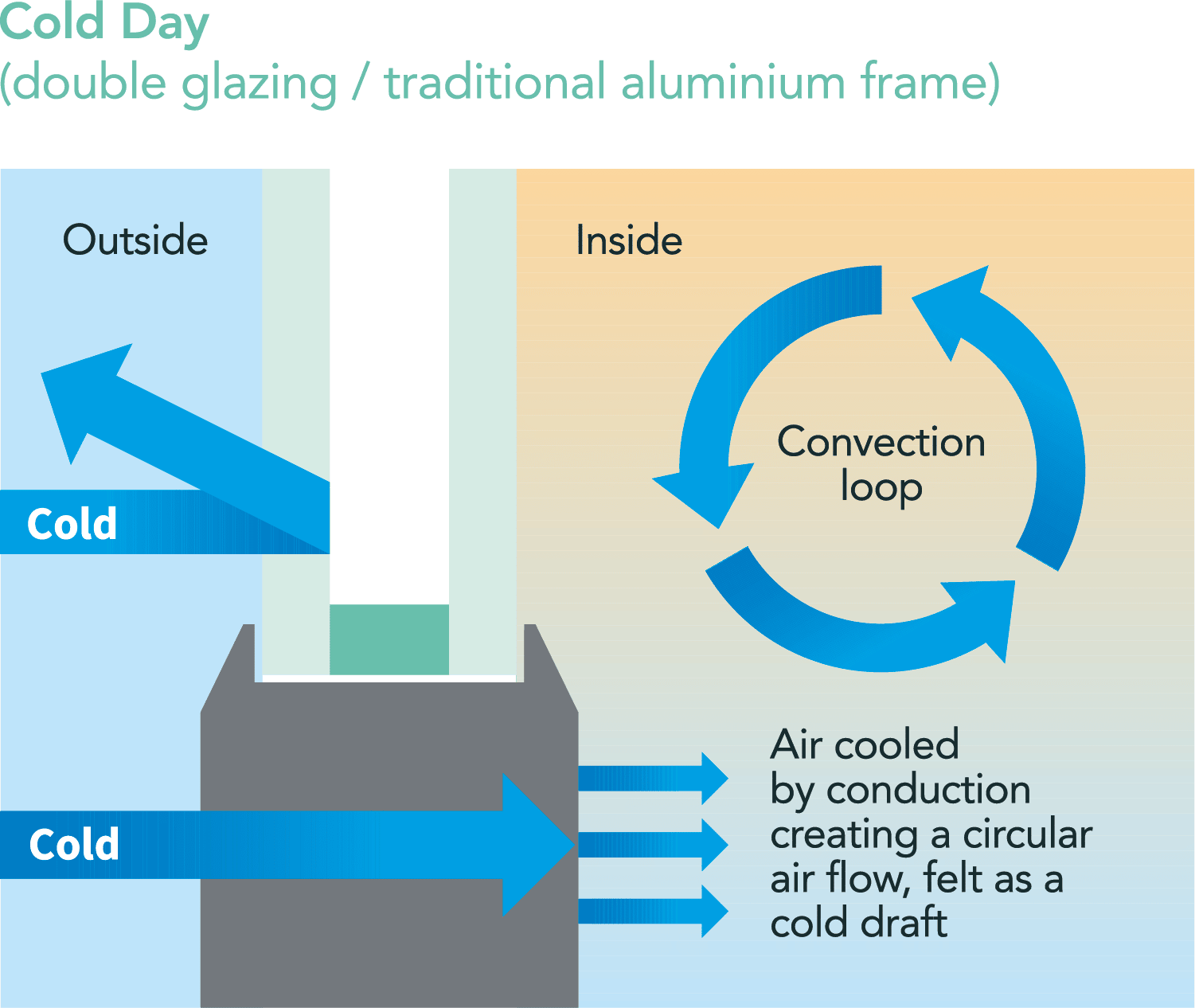

In winter the interior surfaces of a traditional aluminum window frame will be very similar to the temperature outside. When the warm air you’ve heated inside comes into contact with the cold window frame it creates a convection loop which circulates cold air in the room, which feels like draft. By contrast the interior frame of a thermally broken window is much less affected by the exterior temperature. It will stay warmer, reducing convection loops and making the room more efficient to keep at a stable temperature.

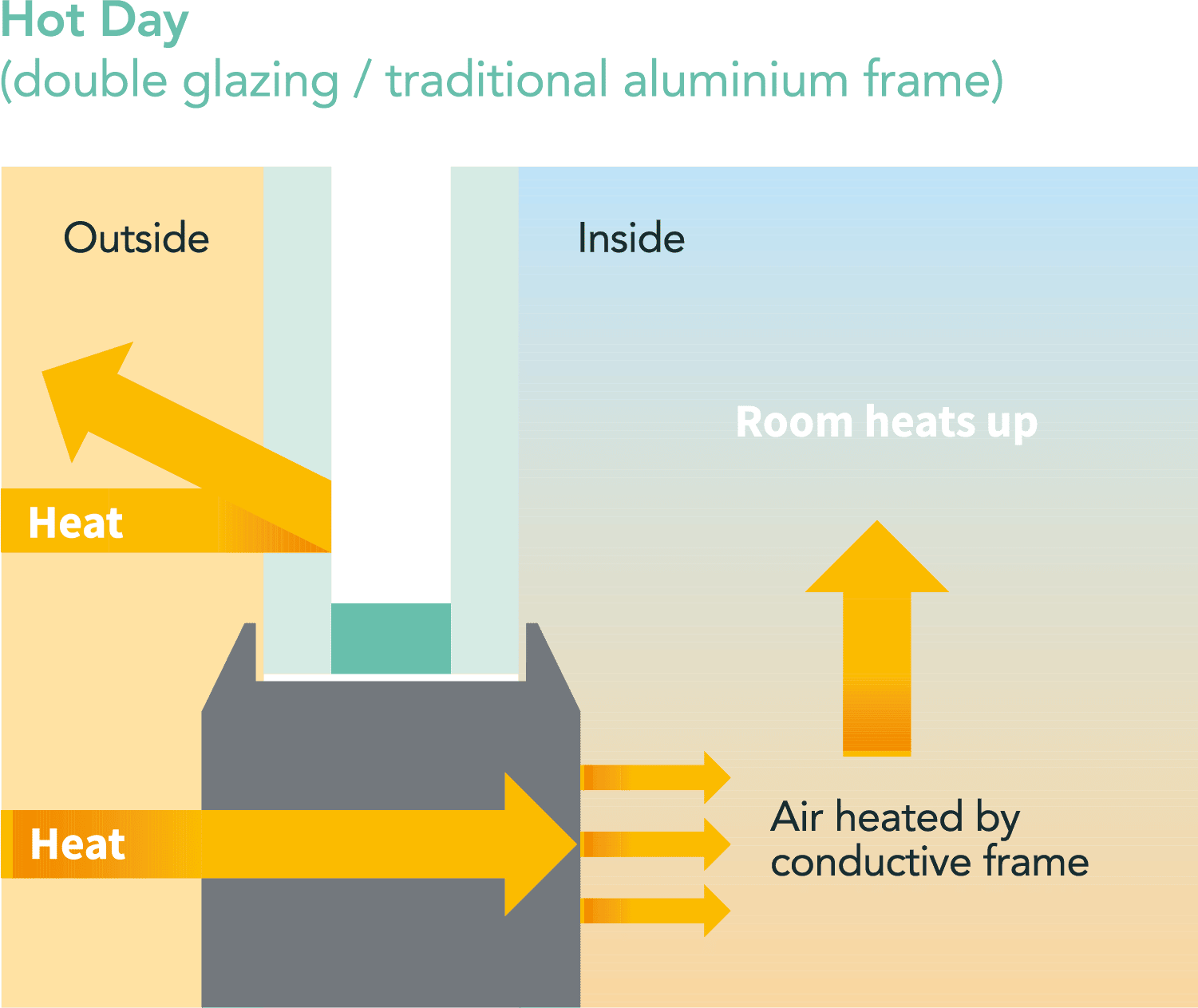

Cooler in summer

In summer the interior surfaces of an aluminum window frame can rise to be significantly higher than the outside air temperature. As an example, in 25°C of outdoor temperature the interior surfaces of dark framed joinery could be as high as 55°C. This increased window frame temperature transfers heat directly into the room making it uncomfortably hot. A thermally broken window frame decreases this transfer of heat so the room can remain significantly cooler. How much cooler depends on the size of the thermal break, the wider the thermal break the more the transfer of heat can be interrupted.

Reduced energy consumption

It’s not unusual to lose up to 50% of the energy used to heat or cool a building through the windows. A traditional aluminum window with standard glass will allow eight times as much energy to escape than through a typical wall of the same area. A windows thermal performance is measured in R value, with a higher number representing better insulating properties. A traditional aluminum window frame with double glazing has an R value of 0.26. Compare that with a thermally broken window frame with double glazing where an R value of up to 0.8 can be achieved, or a thermally broken window frame with triple glazing which can achieve an R value of 1.0.

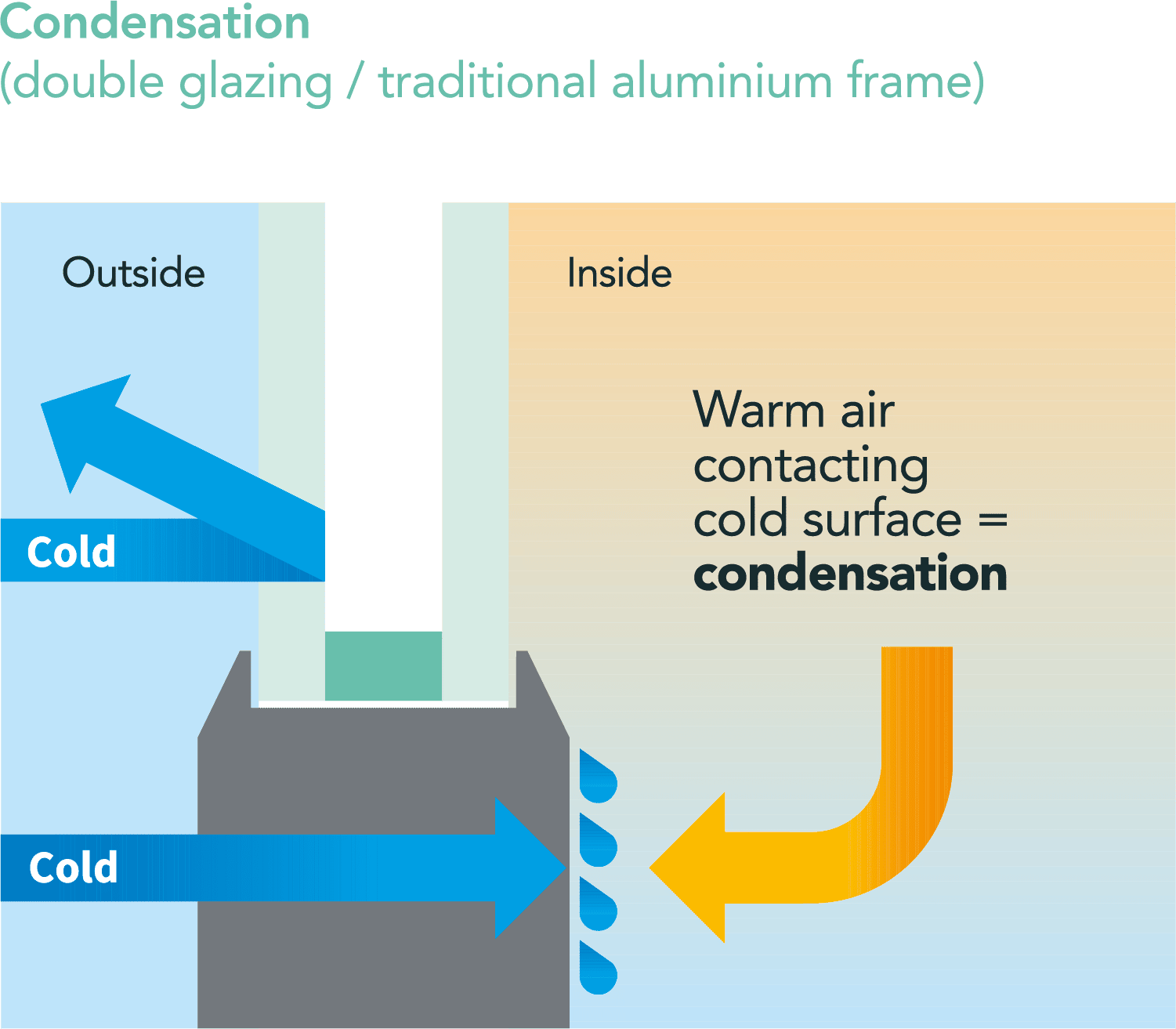

Reduced condensation

Condensation occurs when warm moist air comes into contact with a cold surface. Generally speaking, traditional aluminum frames are the coldest visible surface on a building which is why we often see condensation occurring there first. Because a thermally broken window frame stays at a similar temperature to the interior of the room there’s much less risk of condensation occurring. It must be noted that thermally broken window frames alone are not enough to combat condensation, adequate heating and ventilation are also critical to ensure frame temperatures do not fall below the dew point temperature.