Choosing glass

This guide introduces the most common types of glass used in windows and doors in New Zealand.

At its most basic level, all glass is made by heating sand until it melts and turns into a liquid. Most window glass is made using the float process: a sheet of molten glass is ‘floated’ on a bed of molten tin and drawn out to create a pane that is smooth and flat with a uniform thickness.

By changing the ingredients or process, or adding different coatings, the colour, strength and other properties of the finished glass can be altered to suit different situations. Low iron content, for instance, will produce extra-clear glass.

As well as aesthetics, glass selection impacts energy use in homes, as windows are the greatest source of heat loss in a new build. It’s worth investing in making your windows as energy-efficient as possible – picking special options such as low E glass – for comfort and for lower energy bills.

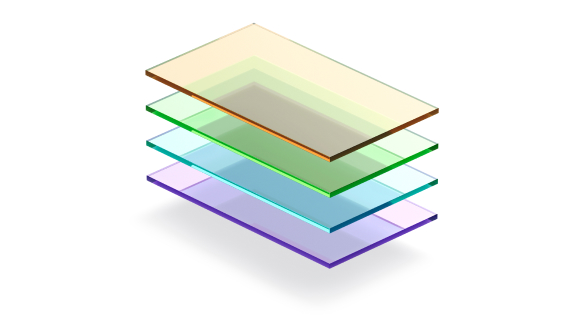

It's important to note that, under the updated New Zealand Building Code, double glazing on exterior windows and doors is a minimum requirement in all new builds. And safety glass is mandatory in many interior applications, such as glazed partition doors and shower glass. To find out more about, read the section on the benefits of double or triple glazing.